不锈钢地板收集器AISI304 1"-5x3/4" Tiemme - 5x3 4

Innovation combined with decades of experience means high-quality solutions and services for your fleet. With our many years of experience in the wind industry, we can support you with the overhaul or replacement of components to ensure high system availability.

Benefit from our global service offers as well as proven logistics and storage concepts available for immediate use in the event of damage.

Prevent gear damage efficiently: The innovative lubricating pinion from Liebherr reliably prevents wear and helps to avoid bearing damage.

Be it slewing bearings for blade adjustment or wind tracking, main bearings, slewing drives, hydraulic cylinders or power electronics: We have successfully been supplying wind turbine manufacturers around the world with reliable and innovative components - and have been doing so since 1996.

With our worldwide production network, the availability of our components and services is optimal, with guaranteed short delivery times and providing you with local contacts only a stone’s throw away. This decreases transport costs, protects the environment and guarantees top-notch service. Together, we can contribute to low-emission power generation.

Wheelbearing noise

EU institutions · European Parliament · European Council · Council of the European Union · European Commission · Court of Justice of the European Union (CJEU) ...

Keep the nose in the wind: Azimuth (yaw) drives optimally align your nacelle with the prevailing wind direction. With yaw drives from Liebherr, you are choosing high-quality, durable and low-maintenance components that extend the service life of your wind turbine.

What happens ifyoukeep driving on abad wheelbearing

Are you looking to open up new markets quickly and flexibly or expand your production capacity? We can help you achieve it with our Liebherr assembly service, thus releasing you of the need to invest in the capital-intensive construction of your own infrastructure.

Spherical Roller Bearings are a type of rolling-element bearing with a barrel-shaped outer ring raceway, complemented by two rows of barrel-shaped rollers.

May 14, 2019 — A wheel bearing is a set of steel balls held together in a metal ring called a race. The race is located inside the hub, and each wheel has one.

Bearings for blade adjustment are subject to special loads like partial standstill, small rotations, and changing loads.

201692 — My requirement is to load the shared library inside a function and then use the QT library , Is there any way I load the QT Library after call of certain ...

How long can you drive with bad wheel bearingswhile driving

Cam Follower. The Cam Follower is a compact bearing with a high-rigidity shaft and a built-in needle bearing. Most suitable as a guide roller for cam mechanisms ...

We already know tomorrow's requirements, today. With our service offerings, we go beyond the components business and give you the support and flexibility you need to be competitive in the market.

How long can you drive with bad wheel bearingsreddit

With components in over 25,000 wind turbines installed worldwide and a vast industry know-how, we offer expert advice, construction and design support for your components and systems. Together we develop the ideas of today and apply them in the products and technologies of tomorrow.

5/8-18X3 1/4 Fine Thread Hex Cap Screw Grade 8 Zinc Yellow. Model #: VF6352CH8O. Quantity of Cartons: Add to Cart & Check Inventory.

Temporary fix forbad wheelbearing

Protect the environment and save money: At our certified locations, we offer you the opportunity to restore your slewing bearing to a perfect, functionally-reliable condition at a low cost.

The sample, analysed in our dedicated oil analysis laboratory, will indicate traces of metals, debris, water or fuel – if present – all of which are flags of a ...

Chicago Rawhide (SKF) Radial Shaft Seal 130X160X15 HMSA10 RG Dual Lip w/One Spring 130 mm Shaft 160 mm OD 15 mm Width, HMSA10 Design Nitrile Rubber (NBR) ...

The global infrastructure of the Liebherr Group offers a wide range of opportunities that are dedicated to serving all of your needs. Our service portfolio includes, but is not limited to the assembly of modules or nacelles. We also develop customer-specific designs to ensure that all components you need are always available.

How long can you drive with bad wheel bearingswithout a

We offer you an all-inclusive package from one single source. Let us win you over with our products, high flexibility and efficient processes.

Benefit from high quality products and a wide range of unique services. With our balanced price-performance ratio, we always go the extra mile for your success.

Wheelbearing replacement cost

DESCRIPTION. Wrapped Construction Single Belts have an outer fabric wrap treated with an engineered synthetic rubber compound that is extremely resistant to oil ...

What are the risks of driving with bad wheel bearings? ... It's very rare for wheel bearings to fail immediately and completely after you notice the first symptom ...

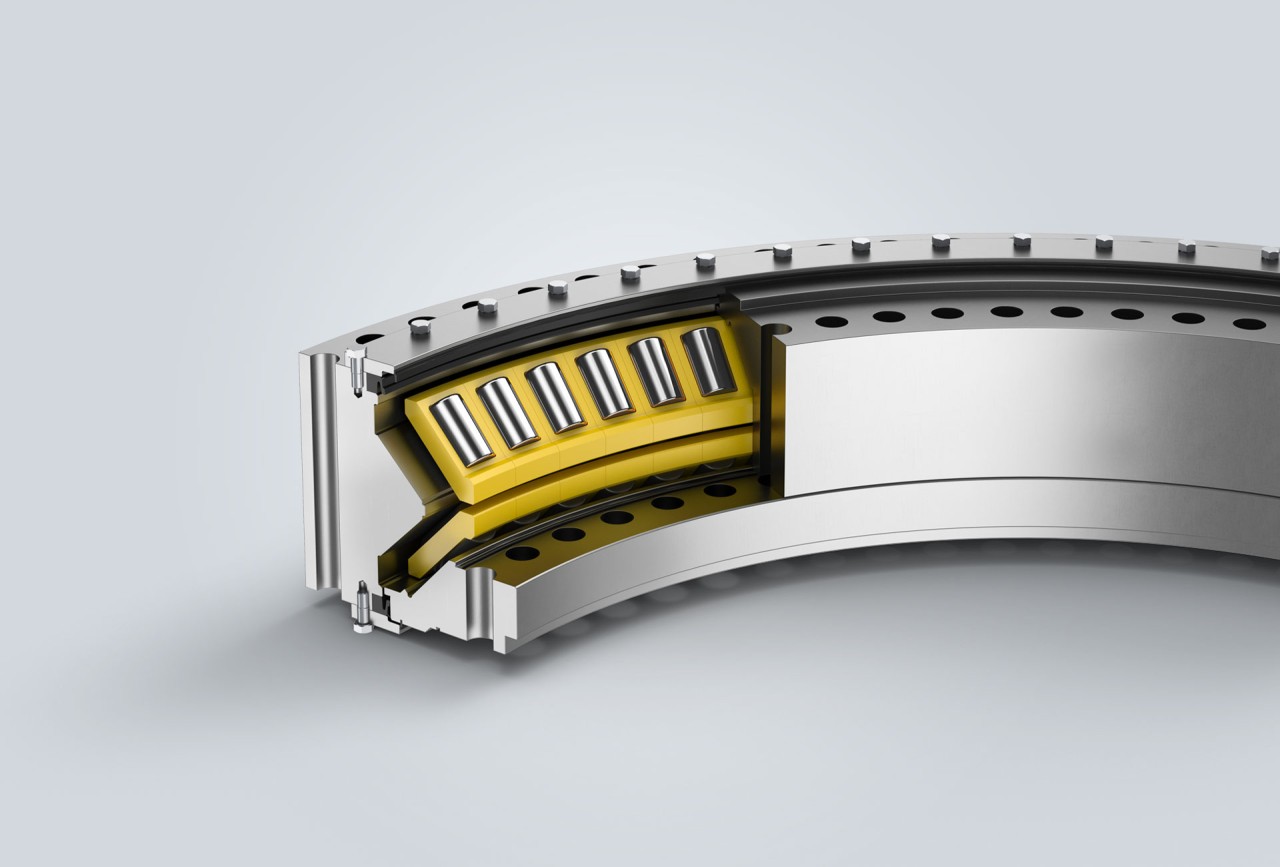

Increase the durability and productivity of your wind turbine with Liebherr blade bearings. In addition to conventional single and double row four-point bearings, Liebherr also offers 3-row roller blade bearings. This design offers great potential in terms of dimensioning and load absorption or capacity.

For example, the wear on your Tires may be uneven and need to be replaced sooner then later. Also, the ride can become pretty rough and bumpy. That can compromise yours and others on the road. Ignoring the grinding, or rumbling sounds, (Wheel Bearing Sound) or the clicking that can occur during acceleration. Are you noticing a vibrating or loose Steering Wheel? You might also experience a pulling when applying the Brakes. Which can cause uneven Rotor and Brake Pad wear, so ignoring the noise can cost you a lot more.

As a reliable partner, we put the longevity of your wind turbine first. This is why we offer spare parts, exchange components, redesign, component monitoring or technical advice and much more. In a nuthshell: We provide the support you need during the entire life cycle of your wind turbine.

Robust and low-maintenance: Liebherr pitch drives are particularly durable and outpace most quality standards. With their resilience and long maintenance intervals, they guarantee permanent availability and the best possible energy yield from your wind turbine.

Liebherr has been further developing its Finite Element Analysis (FEM) of bearings for years. In addition to the bearing, the blade and hub geometry are included in the calculations.

How longwill awheelbearing last once it starts making noise

To increase bearing lifetime and optimize the prevention of idle marks and false brinelling marks, Liebherr co-developed a specialized grease for pitch and yaw bearings:

How long can you drive on a noisy Wheel Bearing? That’s a hard question to answer, the average life of Wheel Bearings is about 5- 10 years or about 100,000 miles. When the Bearings go bad they affect other areas of your Vehicle.

Topping off our wide range of offerings, our portfolio also features engineering services, digital monitoring during product evaluation and consulting services.

Depending on the type of wind turbine, triple-row roller bearings, double-row tapered roller bearings or single-row tapered roller bearings are used as main bearings. While the roller bearing leads to lower stresses in the adjacent construction, the tapered roller bearing is particularly attractive because there is no play, which helps keep functioning of the rolling element optimal. We would be happy to help you the best component.

8613869596835

8613869596835