240 ml/500 ml Film-Seal-Ready lid - 500 240

Sleeve bearingvsbushing

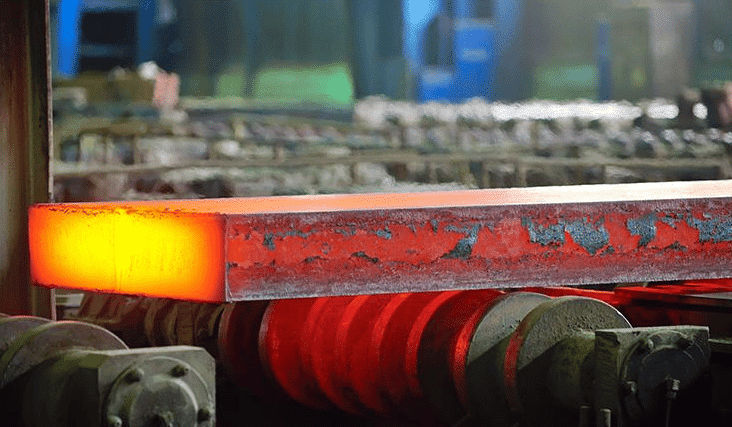

Bushing design, Comprehensive design manuals covering a range of self-lubricating materials used in all of viiplus’s manufacturing processes.

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

After you place your order, we will start the production process. You will receive updates when your order has completed production and is ready to be dispatched.

The Dish Pack Box two layers of corrugated board to protect dishes, glasses and other fragile items.

So, which one should you use? The answer depends on a variety of factors, including the application, load requirements, and environmental conditions. Here are a few general guidelines to consider:

A bushing, also known as a sleeve bearing or plain bearing, is a cylindrical component that is designed to support radial loads and reduce friction between moving parts. It typically consists of an inner and outer cylindrical surface, with a layer of lubricant (such as oil or grease) between them to reduce friction.

Bushing bearing

A bearing is a machine element that reduces friction between moving parts, allowing for smooth and efficient motion. Bearings come in a variety of shapes and sizes, including ball bearings, roller bearings, and plain bearings. Ball bearings are the most common type of bearing and consist of a series of small metal balls held in a raceway. Roller bearings, on the other hand, use cylindrical rollers to reduce friction. Plain bearings, also known as sleeve bearings or journal bearings, have a simple design consisting of a cylindrical sleeve or bushing that rotates around a shaft.

Bushings are typically best for applications that require low to medium load capacity, low speed, or both. They are also a good choice for applications that require simple, low-maintenance components, such as in household appliances or automotive systems.

Bearings are typically best for applications that require high load capacity, high speed, or both. They are also a good choice for applications that require precise motion control, such as in robotics or machine tools.

For roller bearings the amount of elastic deformation is small enough to be ignored. The internal clearance values for each bearing class are shown in Table 8.8.

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

Manufacturing On Demand, Technical Guides For Machining Design. Discover the latest in metal alloys, materials, and design tips for manufacturing custom machined and self-lubricating bearing parts.

We offer CuSn8 solid bronze wrapped sliding bearings. Customized parts with seals or graphite are available upon request.

Each combination of these measurements corresponds to a series number, usually located directly on the bearing. Ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (.394 x 1.181 x .354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

Bushingvsbearing friction

We produce bronze alloys in compliance with global standards. Get in touch with us. Available in various grades, they meet stringent international standards.

The Perfect Spreader For Small to Medium-Scale Jobs. Base Line tailgate models are easy-to-use and perform well for small- and medium-scale jobs. The BL-240 is ...

It is not uncommon that the bearing identification number may be illegible or worn completely after long term use, requiring a bearing to be measured manually. This can easily be done using a vernier caliper to easily provide accurate measurements. If this tool is not available, measurements can be taken carefully using a ruler.

Bearings are measured by their inner diameter, outer diameter, and width; the size of a bearing is normally listed as such: ID x OD x W. These measurements are normally taken in millimeters, but can be converted to inches. In fact, most manufacturers and suppliers offer bearing measurements in both imperial and metric systems.

Three Ways to Drive a Slewing Ring Bearing. Designed similar to ball bearings, slewing ring bearings are used in rotating and turntable applications. The ...

Get a comprehensive guide to bronze bushings. Learn how they are made, their benefits, and how they compare to other types of bronze bushings.

4 Shape Optimization of a Cam ... Maximize the area of the valve opening for one rotation of a convex cam with constraints on the curvature and on the radius of ...

A bushing, also known as a sleeve bearing, is a cylindrical component that is used to reduce friction between two moving parts. Unlike bearings, bushings do not have rolling elements and instead rely on a sliding motion to reduce friction. Bushings are often made from materials such as bronze, brass, or plastic and are commonly used in applications such as hinges, pivots, and pulleys.

Item # BDY22322 · Mfr. Model # 22322 · UNSPSC # 55121704 · CATALOGUE PAGE # N/A · Shipping Weight 0.3 lbs.

Bearings come in various shapes, sizes, and materials to suit different applications and operating conditions. Some common types of bearings include ball bearings, roller bearings, needle bearings, and spherical bearings. Ball bearings are the most widely used type of bearing and are commonly found in machines such as motors, pumps, and conveyors.

Ball bearings are available in all different sizes, depending on the shaft size and requirements of the application. As they are used in all types of industries, they are needed for a large variety of application sizes, from skateboard wheels to oil drills. How are these bearing sizes determined?

As stated before, size depends on the shaft size and application requirements. Bearing size can greatly impact the performance and capabilities of a ball bearing; therefore different sizes are used in different industries.

Bushingvsball bearing

Solid brass bushings available in various bronze alloys including CuSn7ZnPb (RG7), CuSn10, CuSn12, CuPb10Sn, CuPb15Sn, CuAl10Ni, CuSn10Zn (RG10), CuZn25Al5, CuSn5ZnPb (RG 5), featuring lubrication groove designs.

If you are looking for a proper bearing match or replacement, you will also need to pay attention to some other important aspects of the bearing number to find the correct bearing. The suffix can contain a few details about the bearing design and features:

Bushings vs bearings vsballbearings

Bearings and Bushings for the Future: Precision and Customization: Our company, in bearing engineering with decades of experience, designs and develops high-precision self-lubricating bronze bearings & plain bushes. We offer a wide array of sliding bearings tailored to meet specific needs. Renowned for our expertise in custom bronze bushing and slide plate solutions, we provide an expansive selection of bushing metal alloys. Contact us today to benefit from unparalleled services at competitive prices.

Buy 608ZZ Bearing 8x22x7 Carbon Steel Shielded Miniature at wholesale prices in United States. Check reviews and buy today.

In addition to load capacity and speed, it’s also important to consider the environmental conditions that your machinery will be operating in. Bearings are typically better suited for high-temperature or high-vibration environments, while bushings are better suited for low-temperature or low-vibration environments.

bearings and bushings are two distinct components that serve different purposes in machinery and equipment. Bearings are versatile components that can handle high loads and high speeds, making them a good choice for many applications. Bushings, on the other hand, are simple and cost-effective components that are best suited for low-load and low-speed applications. By understanding the differences between these two components and considering the specific needs of your application, you can choose the right component for optimal performance and longevity.

Triple-sealed bearings feature a secure bearing seal with three lips. This special seal offers reliable dustproofing and waterproofing superior to those of ...

Bushings vs bearingsreddit

Each manufacturer may use unique suffix codes; it is best to look up a suffix guide to find the correct bearing match or replacement.

If you’re involved in machinery or equipment manufacturing, you’ve likely come across the terms “bearing” and “bushing” at some point. While these two components may seem interchangeable, they actually have distinct differences that can affect the performance and longevity of your machinery. In this blog post, we’ll take a closer look at the differences between bearings and bushings, their respective advantages and disadvantages, and which one you should use in different scenarios.

A bearing is a precision component that is designed to support radial and/or axial loads and reduce friction between moving parts. It typically consists of an inner race, an outer race, rolling elements (such as balls or rollers), and a cage or retainer that holds the rolling elements in place. The rolling elements roll between the races, which reduces friction and enables smooth rotation or oscillation of the shaft.

Tailored design and guidance for bearing bushing materials, including selection guides for sliding materials and bushing types.

Get all the information you need about bronze flanged and plain bushings. Find out how they compare to other materials and why they may be the right choice for your application.

Bushings vs bearingsairsoft

One of the main advantages of bushings is their simplicity, which makes them easy to install and replace. Bushings are also less expensive than bearings, making them a cost-effective choice for many applications. However, bushings are typically less durable than bearings and can wear out more quickly. They also have a lower load capacity than bearings, which can limit their use in certain applications.

Mar 6, 2018 — -Types of Bearings · Radial Ball Bearing. – When you think of a bearing, this is often what you are imagining. · Pillow Block Bearing · Cam ...

Bushings vs bearingspros and cons

Generally, smaller ball bearings have more limited load capacities. They are used in applications where space-efficiency is more important than load capacity. Miniature bearings, often constructed as precision ball bearings, are used for extremely small applications, such as medical instrumentation, robotics, or semiconductor equipment. On the other hand, larger bearings have greater load capacities. They are used for heavy-duty industries such as agriculture machinery, mining and drilling equipment, or heavy power tools. Many manufacturers also offer custom bearing size options for very specific applications that have unique requirements.

The standard dimensions for skateboard bearings are 8mm for the core diameter, 22mm for the outer diameter, and 7mm in height. Bearing size ...

Browse our selection of high-quality bronze bushings for sale. Whether you need a replacement or are starting a new project, we have the right fit for your needs.

Reduce downtime, increase self-lubricating bearing service life & save cost for moving applications. Get Your Instant Quote

Bushings come in various materials, including bronze, brass, steel, and plastic, to suit different applications and operating conditions. They are commonly used in applications such as electric motors, automotive suspension systems, and hydraulic cylinders.

8613869596835

8613869596835