04-S1701 1.0 X 19.0mm Wire Pass Bur - 19.0mm

Overall, radial flux motors offer simplicity in construction, efficient heat dissipation, durability, versatility, and cost-effectiveness, making them a preferred choice for many industrial and commercial applications.

In conclusion, the comparison between axial flux and radial flux motors highlights the importance of understanding their distinct characteristics and applications.

Cost-Effectiveness: Due to their simpler design and widespread availability, radial flux motors often offer a cost-effective solution for applications where high performance is not the primary consideration.

Galvanized steel duct pipe 8 in x 60 in x 30 GA. Improved reeves for easy and safe locking. For furnace installation or air exchanger.

By carefully analyzing these factors, engineers and designers can select the most suitable motor type for their specific application needs.

... CAP SCREWNORD LOCK WASHERHIGH TENSILE ALLEN BOLTHT 12.9 GRADE ALLEN BOLTSECURITY SCREWGRUBDUPLEX 2205 ALLEN BOLTDUPLEX 2205 SOCKET HEAD CAP SCREWSS 304 COTTER ...

Whether you’re an engineer looking to optimize motor performance or simply curious about the latest technological advancements in electric motors, this blog is your go-to resource for understanding the intricacies of these two motor types. So let’s dive in and unravel the mysteries behind axial flux versus radial flux motors!

Renewable Energy Systems: They are widely used in wind turbines and solar trackers to harness renewable energy efficiently.

Electric Vehicles: Axial flux motors excel in electric vehicle propulsion systems due to their high power density and efficiency.

Density: 3.21 g/cm³Thermal conductivity: 120 W/m•KCap filling weight: 2.2 g Enough to fill one Tempest Cap and some extra. 2.5mm - Approx 100pcs3mm - Approx ...

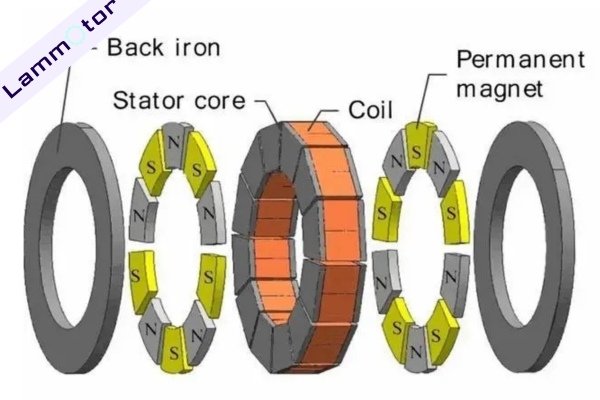

When comparing axial-flux with radial-flux magnetic topologies in electrical motors, the main difference lies in the flux direction. While radial designs use a radial flux permanent magnet configuration, axial designs utilize a yokeless axial flux permanent magnet. The radial design leverages a transverse flux path, whereas the axial design allows for a nearly uniform magnetic field to be generated.

Industrial Machinery: They find extensive use in industrial equipment like pumps and compressors, where durability and reliability are paramount.

Axial flux machines generally exhibit higher efficiency levels compared to radial flux machines. This is primarily due to the more direct path of magnetic flux in axial flux motors, resulting in reduced energy losses during operation.

Higher Power Density: Axial flux motors offer a higher power output relative to their size and weight compared to radial flux motors. This increased power density makes them ideal for applications where space and weight constraints are critical factors.

Compact Design: The axial configuration of flux paths allows for a more compact motor design, making axial flux motors suitable for installations where space is limited. This versatility in size and shape enables their integration into a wide range of applications, from small-scale devices to large industrial machinery.

Both axial and radial flux motors play vital roles in renewable energy systems, powering applications such as wind turbines and solar trackers. They contribute to improving the efficiency and reliability of these systems, thereby promoting the adoption of renewable energy sources.

Axial flux motors are more suitable for electric vehicles due to their higher power density and efficiency, which are crucial for optimizing performance and range.

Weight and Dimensions · Inner (d) MM 8 · Outer (D) MM 22 · Width (B) MM 7 · Inner (d) Inch 0.315 · Outer (D) Inch 0.8661 · Width (B) Inch 0.2756 · Weight (kg) 0.012 ...

A radial flux motor is a type of electric motor where the magnetic flux travels radially, moving from the center of the motor outward toward the circumference. In radial flux motors, the stator surrounds the rotor, and the flux travels through the stator and crosses the air gap to reach the rotor. This design is commonly found in conventional motors such as induction motors and permanent magnet synchronous motors.

Axial flux motors have magnetic flux flowing parallel to the shaft, while radial flux motors have flux flowing radially. Axial flux motors offer higher power density and efficiency but are generally larger. Radial flux motors are simpler in design but may have lower efficiency.

Axial flux motors tend to be more compact and lightweight than radial flux motors, making them preferable for applications where space and weight constraints are critical factors.

The axial flux stator and rotor are arranged in a disc-like configuration, with the stator and rotor disks sandwiching the air gap where the magnetic flux travels. This design offers advantages like higher power density, efficiency, and torque-to-weight ratio compared to traditional radial flux motors. Axial flux motors are commonly used in various applications including electric vehicles, wind turbines, and industrial machinery.

Aerospace: Axial flux motors power various aerospace applications, including UAVs and electric aircraft, where lightweight and compact designs are crucial.

What is the new T+1 settlement deadline for trade matching in Canada and the US? Under the US SEC rules, the regulator expects a 100% matching at 9:00 pm EST on ...

In this article, we’ll delve deeper into the intricacies of axial and radial flux motors, exploring their mechanics, benefits, applications, and the factors influencing their selection.

Enhanced Efficiency: Due to their unique design and magnetic flux flow parallel to the motor’s shaft, axial flux motors exhibit reduced energy losses, leading to higher overall efficiency. This translates to improved performance and lower operating costs over the long term.

While axial flux motors may have higher upfront costs due to their advanced design and technology, they often offer greater efficiency and durability, resulting in long-term cost savings. On the other hand, radial flux motors typically have simpler construction and lower initial costs but may require more frequent maintenance and replacement over time.

Wide Range of Applications: Radial flux motors are versatile and can be used in various industries, including household appliances, automotive systems, and manufacturing equipment.

Enhanced Durability: The robust construction of radial flux motors contributes to their durability and longevity, making them suitable for demanding industrial applications.

While axial flux motors offer advantages such as higher power density and efficiency, radial flux motors excel in simplicity and cost-effectiveness. The choice between these motor types depends on various factors including efficiency requirements, space constraints, and cost considerations.

While radial flux motor is widely used and well-established, they typically exhibit lower power density and efficiency compared to axial flux motor in certain applications due to their design limitations.

Yes, axial flux motors can be used in small-scale applications due to their compact design and versatility. They are ideal for applications where space constraints are a concern.

THIS LISTING IS FOR ( 1 ) PIECE - N 319 ECP - SKF - CYLINDRICAL ROLLER BRGS - FACTORY NEW!

Lammotor is a motor core lamination manufacturer based in China. We are passionate about providing our customers with the highest quality of products, and we have been doing so since our founding in 2010.

Notable drawbacks of radial flux motors include potentially lower efficiency compared to axial flux motors and limitations in power density and torque output.

An axial flux motor is a type of electric motor where the magnetic flux flows parallel to the motor’s rotational axis, as opposed to radial flux motors where the flux flows radially from the center outward.

When comparing axial flux and radial flux motors, several factors come into play, influencing their suitability for various applications.

Simpler Construction: Radial flux machines typically have a simpler design compared to axial flux motors, resulting in easier manufacturing processes and lower production costs.

Axial flux and radial flux motors represent two distinct categories of electric motors, each with its unique design and functionality. Axial flux motors feature a design where the magnetic flux flows parallel to the motor’s shaft. In contrast, radial flux motors have a magnetic flux that flows radially inward or outward from the center of the motor. These motors play a crucial role in various industries, powering everything from electric vehicles to industrial machinery and household appliances.

Reduced Weight: Axial flux machines are typically lighter than their radial flux counterparts, contributing to overall weight savings in systems where weight reduction is crucial. This feature is particularly advantageous in applications such as electric vehicles and aircraft, where minimizing weight is essential for efficiency and performance.

This page introduces tapered roller bearings. The tapered shape enables a long line contact, making this bearing suitable for applications with heavy load ...

Better Heat Dissipation: The radial flow of magnetic flux in these motors allows for efficient heat dissipation, reducing the risk of overheating and enhancing overall reliability.

As technology continues to evolve, both axial and radial flux motors are expected to play significant roles in powering diverse applications, driving innovation, and contributing to the advancement of sustainable energy solutions.

Reliable Quality And Discounted Price 70-110mm Ball Bearing Steel Centre Polyurethane PU Rollers. Tread:polyurethane. Type:pu wheel. Centre:iron

Flexibility in Installation: The compact and lightweight nature of axial flux motors facilitates easier installation in various configurations, offering flexibility in design and deployment. This ease of installation makes them a preferred choice for industries seeking efficient and reliable motor solutions.

Household Appliances: Radial flux motors are preferred in appliances such as washing machines and refrigerators due to their simpler construction and cost-effectiveness.

Overall, the key benefits of axial flux motors include higher power density, enhanced efficiency, compact design, reduced weight, and installation flexibility, making them well-suited for a wide range of applications across different industries.

... , and machinery needs. Experience enhanced durability, high-precision, and superior efficiency with our W2X bearings. Visit us for all your bearing solutions.

Automotive Systems: Radial flux motors are commonly used in automotive applications such as HVAC systems and power steering due to their versatility and cost-effectiveness.

Axial flux motors often offer higher power density, allowing them to deliver greater torque in a smaller package compared to radial flux motors. However, radial flux motors may excel in applications requiring lower torque but higher rotational speeds.

Pioneering Innovation. Harnessing creativity and technology, we transform properties into high-performing rental assets that ensure optimum returns.

8613869596835

8613869596835