ZW-03-11-T-D-600-230 Samtec Inc. - 600-230

Also, it’s worth mentioning that as soon as you start to recognise that you have worn wheel bearings, it should be addressed immediately and the bearings should be replaced by a professional mechanic.

Snapping, clicking or popping sounds coming from the wheels of your vehicle may also indicate there is an issue with your bearings. Whilst it is often an indicator of a CV joint issue, it could also be due to inadequate bearing clamping. You might hear this sound slightly increased when you make sharp turns around corners.

Aubearing attaches great importance to investing in advanced manufacturing equipment and high-precision testing instruments:

If you are looking for high quality mounted bearings, look no further than UCFB. These bearings are known for their durability and reliability, making them a popular choice for a variety of industrial and commercial applications. UCFB housed bearings are designed to support heavy loads and provide stable, consistent performance over time. They are constructed from high-quality materials, including precision-machined steel and advanced polymers, ensuring they can withstand the harshest conditions. One of the main advantages of UCFB mounted bearings is their ease of installation and maintenance. They are designed to fit seamlessly into a variety of applications and require little ongoing maintenance or lubrication. Whether you are in manufacturing, construction, mining or any other industry that requires durable and reliable bearings, UCFB pillow block bearings are an excellent choice. With high-quality materials, advanced designs, and long-lasting performance, they’re sure to give you the support you need for years to come.

Shaft Diameter – The diameter must match the appropriate bore diameter of the bearing unit. Properly sized pillow block bearings slide easily onto the shaft and into position, ready to be secured with a locking device.Shaft Height – Shaft height or backing height is determined by measuring the distance from the base of the pillow block bearing to the center of the shaft.Shaft Size – The maximum diameter of the shaft or the diameter of the bore into which the bearing is mounted.Maximum Speed – The maximum shaft speed a bearing is designed to allow for operation.Maximum Load – The dynamic load capacity of a bearing capable of carrying both radial and thrust loads, or the maximum allowable radial load of a bearing capable of carrying radial loads only. The load rating varies with shaft speed. Consult the manufacturer for load ratings at various shaft speeds.

8. The grinding processing equipment of the bearing rings uses high-precision special CNC grinders to ensure the accuracy of each surface of the bearing rings, so that the bearings have low friction resistance and high rotation accuracy when rotating.

It’s inevitable that every time you drive your vehicle, your wheel bearings will wear a little, just like any other component. However, there are certain things that can cause them to wear out at a quicker rate. Above we mentioned the symptoms of worn bearings and now we will be discussing what can cause them to become damaged prematurely.

In regard to abnormal tyre wear, this symptom can be caused by quite a few problems, such as worn shocks and struts, unbalanced tyres or even misaligned wheels. Therefore, it’s important to consult a professional before making any assumptions.

Pillow block bearing plays a key role in mechanical equipment. It not only supports the power system and main parts of the equipment, but also helps the equipment operate smoothly and reduce equipment damage. Therefore, choosing the appropriate pillow block bearing is one of the important factors to ensure the efficient and stable operation of the equipment. It is also a key factor to ensure the life and reliability of the equipment.

When your car hits around 100,000 miles, it is recommended that you replace both bearings on the axle at the same time, if you have never had them replaced before. Make sure that you get a professional to check any noise that may be coming from your wheels or tyres; in some cases, there could be an issue with your tyres, rather than the wheel bearings.

9. The important surfaces of the inner and outer rings of the bearing must be tested for roundness using a high-precision roundness meter. In addition, it is equipped with a precise profile and roughness inspection instrument for precise detection of the shape and roughness of the grinding surface;

Any vehicle that has wheels will have wheel bearings, such as bicycles, aeroplanes and even boats. They consist of a group of steel balls attached to a metal ring, which is located on a metal axle shaft. The axle is positioned inside the wheel hub, which is the mounting assembly for the wheel of the vehicle and this hub also houses the lugs nuts that are used to bolt the tyre to the wheel. When the wheels of your vehicle turn, the bearings help to speed up their rotation and reduce the amount of friction, which in turn, creates a smooth experience for the driver.

1. The bearing seat is cast using a medium-frequency electric furnace for smelting. It is equipped with raw material element analysis instruments, metallographic microscopes and molten iron element detection analyzers in front of the furnace. It can accurately detect the chemical composition of the smelted molten iron, thus ensuring the mechanical properties of the castings;

Power Steering Services is based in Greenwich, London and we offer a range of high-quality services. If you are suffering from any of the symptoms of worn wheel bearings, we can diagnose if your bearings are in fact damaged or incorrectly installed, and we can then offer the necessary service, whether it be readjustment or replacement. Book in with us today, either by filling in our easy online form or contacting us on 0208 853 3343.

UCF series Pillow Block Bearing, is a variation of deep groove ball bearings. The outer diameter surface of the outer ring is a spherical surface, which can be fitted into the corresponding concave spherical surface of the bearing seat to achieve alignment. The outer spherical bearing is mainly used to bear the combined radial and axial load, which is mainly radial load. It is not suitable to bear the axial load alone.

Floods and Flooded Streets: When you drive in a flooded street or through long, deep puddles, the seals on the wheel system will not be able to stop the water from entering your wheel bearings. Even though they have seals, if they are exposed to water for an extended period of time, they will eventually wear out and need to be replaced. All the wheel bearings are already lubricated when the car is manufactured, with a petroleum-based mixture which does not mix well with water. In the worst-case scenario, too much water exposure can cause the grease to come off and then damage will be caused because of the lack of lubricant.

The complexity of the replacement procedure usually depends on the model and make of the vehicle. It also depends on where the bearing is located (front or rear) and the vehicles drive type (all-wheel drive or front-wheel drive). Here is a basic outline of what steps your mechanic could follow when replacing your bad wheel bearings:

UCT Pillow Block Bearing, wider inner ring bearing, set screw locking, cast gray iron housing. Cast ductile iron bearing housings are available on request. The UCT series tensioning ball bearing unit is a Pillow Block Bearing unit, which consists of a T-shaped bearing seat and Pillow Block Bearing. The bearing seat is available in cast iron, ductile iron, plastic and stainless steel material designs. UCT series Pillow Block Bearing can be designed in chrome steel and stainless steel. The material selection needs to be determined according to the application of the installed bearing unit. The most commonly used on the market is a cast iron housing with chromium steel outer spherical bearings. Stainless steel and plastic UCT tension bearing units are commonly used in the chemical and food industries.

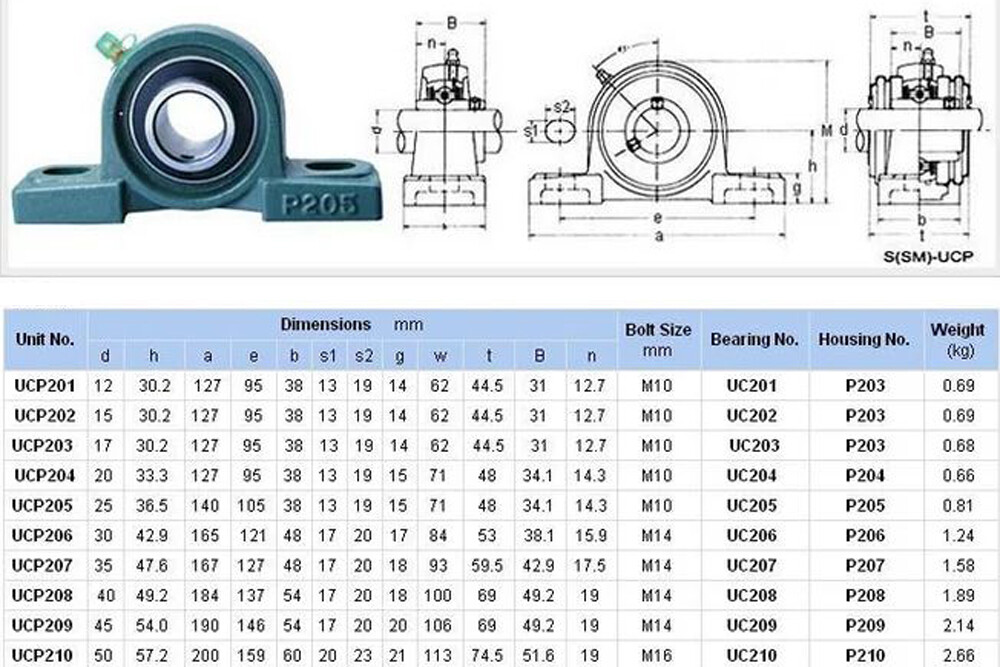

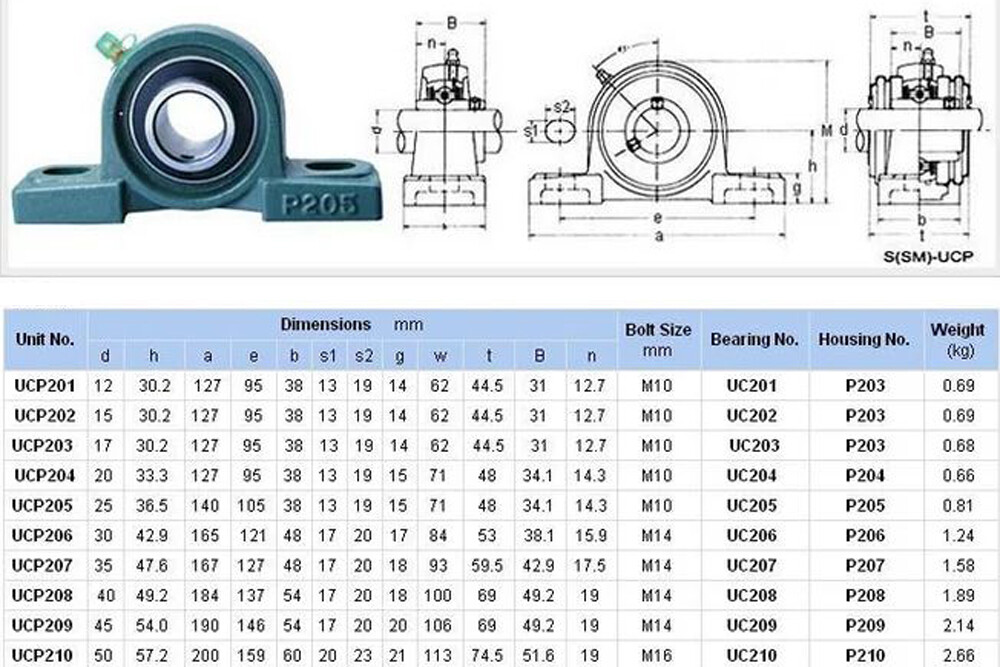

The UCP series of seated outer spherical bearings is a representative form of seated outer spherical bearing components. Among them, the bearing seat P refers to the flat bottom solid. This series has two types: UCP200 and UCP300. The UCP300 series carries a larger load than the UCP200 series. Because there are reinforcement ribs at the root of the bearing seat installation part, it is a high-strength structure for loads in all directions. In addition, the bearing seat P can also be used with UK, UEL, NA series bearing assemblies, and UK assemblies with tapered bores (UKP). The nominal model number of the applicable adapter sleeve is appended to the component engineering model. Main uses of UCP series Pillow Block Bearing: transmission devices, fitness equipment, harvesters, etc.

Clutch/Neutral Gear Issue: You may notice that your vehicle has a difficult time rolling when the clutch is down and you are in neutral gear. If the wheel bearings are worn out it will create friction in your wheel bearing system.

You may hear it from one side only, rather than both at the same time. It is more common that it will only be coming from one wheel, and you will probably also notice some tyre wear on the same side as where the noise is coming from. When your bearings do start to lose efficiency, it happens very quickly, which is why it’s important to keep an eye out for any bad wheel bearing sounds.

If you’ve been hearing strange noises from one of your wheels and then this occurs, you will need to cease driving your vehicle in this condition and take it to a garage, where the issue can be diagnosed and the bad bearing can be replaced if necessary.

The short answer is no. it is not recommended that you drive your vehicle if you suspect that your wheel bearings are damaged or faulty. Failure of your bearings is a gradual process, but it could be caused immediately after hitting a pothole or having another kind of sudden impact to the wheel, such as a car accident.

The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

Grinding Or Roaring Noises From Your Wheels: If you start to hear a loud roaring or grinding sound coming from the tyre area, then you may be dealing with bad bearings. The sound can resemble metal moving against metal and it’s usually due to the loss of lubrication in the bearing, which is caused by too much heat building up in it.

Due to its excellent structural characteristics, pillow block bearing is widely used in various mechanical equipment, such as metallurgical equipment, mining equipment, water pumps, fans, machine tools and other fields. At the same time, pillow block bearing can also withstand certain radial and axial loads, so it is also commonly used in automobiles, motors and other industries.

Agriculture: used in agricultural machinery such as tractors and harvesters.Mining and Construction: Heavy machinery and construction equipment employed in mining operations.Food Processing: Suitable for food grade applications, providing hygiene and durability.Manufacturing: Used in conveyor systems, assembly lines and automated machinery.

On some vehicles, the wheel bearings are pressed onto the axle shaft. The axle must be taken out from the axle carrier in this case.

Most vehicles are equipped with a maintenance-free wheel bearing which is designed to last a lifetime of the vehicle, but even these are still prone to wear and tear eventually, and will still need to be serviced to make sure that they are in working order.

However, if there is an issue with one of your bearings, then depending on the condition of the others on the same axle, your mechanic may recommend that you replace them all at the same time. However, some dishonest mechanics may claim that you need them all replaced when you don’t really need to, which is why you need to make sure you take your vehicle to someone trustworthy.

10. The bearings are assembled using a variety of automated equipment such as fully automatic ultrasonic cleaning, automatic bearing assembly, automatic grease injection, and automatic capping;

Depending on what type of wheel bearings you have, they can last anywhere between 70,000 to 150,000 miles. You could have unsealed bearings, which can be taken out to be cleaned and re-greased. Or you could have sealed ones, which you will not be able to lubricate and would instead require a professional to do this for you. Similar to how engine oil prevents the engine from failing, by keeping the components lubricated, your bearings need to be greased properly or they could become damaged.

Luckily, there are obvious symptoms that occur when your wheel bearings may be faulty or need some attention. It’s important that you always look for these signs because having faulty or damaged wheel bearings could cause a lot of damage to your wheel system, and also create a lot of issues whilst driving on the road.

Unbalanced tyres: If there is an uneven distribution of weight around the wheels, it will mean that certain wheel bearings are subjected to more pressure than others, which can cause them to wear at different rates. You may begin to notice that your wheel will become noisy and then the damage has already begun to occur.

Your Vehicle Pulling To One Side: This symptom, again, can be caused by other problems, such as misaligned wheels, a stuck brake calliper or worn suspension components. However, a bad wheel bearing can also be the culprit.

Bad or Faulty Installation: If you have just got your wheel bearings replaced and you’re already experiencing issues, such as a strange grinding noise and abnormal tread wear, the mechanic who installed them may have done so incorrectly or not to the manufacturer’s specification. Sometimes, human error cannot be avoided, but it is best you take your vehicle to the original place you purchased your car from and make sure that the correct bearings are installed and adjusted correctly.

Aubearing is China’s leading UCFB mounted bearing manufacturer, supplier and factory. UCFB housed bearings are designed to provide reliable, efficient performance in a variety of industrial applications. UCFB housing bearings are made of high-quality materials and feature a sturdy base design to provide better support and stability for heavy loads. With superior sealing and lubrication systems, they provide long-lasting durability and high performance even in harsh operating environments. UCFB housed bearings are available in different sizes and configurations, making them suitable for a wide range of applications in various industries, including agriculture, mining, construction and . At Aubearing, we are committed to providing our customers with high quality UCFB housed bearings to meet their specific needs and requirements. Please contact us today to learn about our products and services.

Wheel bearings are designed to support the front and back axle and the weight of your car. They are made out of hard steel, created using a high-precision technique that is designed to withstand all of the regular impacts that the wheels and tyres face, as your vehicle is driven on the road. The bearings consist of rolling parts, such as ball bearings or roller bearings. These roll around on the hardened steel bearing races.

Part of good car maintenance is to make sure that all of your tyres are balanced. Some common symptoms of unbalanced tyres are uneven tread wear, low fuel economy and vibrations in the steering wheel. Therefore, it’s important to carry out this service, to keep your vehicle running smoothly and put equal amounts of pressure on all of your wheel bearings, so none of them needs replacing prematurely. You can do this by taking your car to a professional, or have them checked whilst your vehicle is being serviced.

Housing bearings must comply with industry standards and regulations to ensure quality and safety. Some widely recognized standards include those developed by the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO).

Aubearing is a manufacturer specializing in manufacturing a full range of Pillow Block Bearings as well as non-standard customized bearings and bearing seats: Based on years of manufacturing experience, we have summarized the size table of the full range of pillow block bearings to provide you with a reference for purchasing suitable bearings. If you have any questions, please contact an Aubearing expert today.

Abnormal Tyre Wear: You would be lucky if all of your wheel bearings wear out at the same rate, however, we don’t live in a perfect world. Therefore, if one is worn, it’s likely that the same tyre will also wear out quicker compared to the others. For example, if the right tyre on your vehicle is showing signs of wear more than the left, this may mean that there is a problem with the right wheel bearing.

The UCFC200 series is a bearing assembly composed of a bearing and a bearing seat with a circular seat and a boss on the mounting surface. It has advanced concepts in design and manufacturing and has accumulated rich experience. The bottom surface of this series of seats has a circular The boss can be placed in the round hole of the frame, with high installation precision and accurate positioning. Main uses: wheat harvester, corn harvester, etc.

6. Then the bearing rings will be sent to the protective atmosphere heat treatment production line for quenching heat treatment and tempering treatment. Especially large-size bearing rings adopt advanced salt bath quenching process, which greatly ensures the inherent quality of the bearing rings and makes the bearings durable. Longer service life and higher reliability;

3. The bearing seat is machined using a variety of special machine tools to ensure the accuracy of the bearing seat. In addition, the company also makes and renovates existing machine tools internally, which greatly improves processing accuracy and production efficiency;

Car Accidents: If you have been in an accident where your wheels have collected some damage, you should check if your wheel bearings are in good condition, as it is possible that they could have been affected by the impact too. It’s good to check that no unusual noises are coming from the wheels and that your wheels are functioning adequately. It is best to have them checked by a professional to ensure you are not a hazard on the road.

This component is meant to have a smooth surface, to allow the wheel hub assembly to rotate smoothly and in turn, the wheels to turn fluidly. When a wheel bearing begins to wear out, its smooth surface may become rough due to wear and tear and this can trigger the grinding noise from that specific tyre and vibration from the steering wheel. Also, the vehicle may begin to pull to the side. For example, if your left wheel bearing is damaged, then you may feel your vehicle veering to the left.

When the engine produces power, the power gets converted in the transmission, which then helps transfer power to the wheels of the car. The drive shafts go through the hub assembly on a vehicle and then rotate them. For the shafts to remain in place, a wheel bearing must be secured around them. Therefore, when the car is put in drive or reverse, the wheel bearings have to do their job. They also prevent your tyres from building up too much heat.

5. The raw materials of the bearing rings are produced from high-quality bearing steel from Xingcheng Steel Plant and Daye Special Steel. In particular, the inner and outer rings of medium and large-sized bearings are made of forging blanks, which are then turned by precision CNC lathe turning lines;

Aubearing has introduced 5 fully automatic casting production lines with Japanese technology, with an annual output of 12,000 tons of gray and ductile castings; it has advanced special equipment for machining of bearing seats, fully automatic electrostatic spraying equipment for bearing seats, and continuous cleaning, dehydration and rust prevention of bearing seats. production line, with an annual output of 8 million bearing seats; it has industry-leading bearing ring grinding and processing production lines and bearing cleaning and assembly production lines, with an annual output of 8 million sets of bearings.

Sometimes, the unusual wheel bearing noise could be present for a while before the issue becomes a serious hazard. When the wear on the bearing slowly increases, it’s hard to predict when it will fail, and this is the reason why it is best not to drive with this issue. If you ignore or delay the replacement of this worn component, you will run the risk of it breaking or seizing while you are driving and you will lose control of the vehicle.

Uneven Roads: If we told you to imagine a rough and bumpy road, you can probably name a few… dozens. Let’s just say a common issue these days is the poor quality of the roads, especially since they’re littered with potholes! So, think of the beating your wheel bearings receive when your wheels are travelling on these uneven roads. The chances of them collecting damage is high and then this can cause more friction for the wheels, as the bearings will become too worn.

Bearing seat FL can be combined with UC to form two series, UCFL200 and UCFL300. Similarly, it can also be used with UK, UEL (NA), UB, SB and other components. The UCFL series combination has a lightweight structure and is easy to install. It is suitable for installation in small transmission parts. Like the UCF series, it is suitable for installation on vertical surfaces such as the side of machinery. over, due to the center distance of the two mounting bolt holes of the diamond bearing seat The center distance of the two diagonally located bolt holes of the square bearing seat is the same, so they are interchangeable with each other. The SBLF200 series of seated outer spherical bearings are diamond-shaped bearings designed for the purpose of lightweighting. This series has a total of 7 models from SBLF201 to SBLF207. Bearing seat LF can also be assembled with UB (SB) and UE (SA). This type of product is mainly used in packaging machinery, fruit sorting machines and other equipment.

Pillow block bearing is a bearing used in low torque, light load applications. It consists of a mounting bracket or pillow block that houses the bearings. The spherical rolling elements in pillow block bearings have a smaller contact surface with the bearing raceway, which reduces friction. Low friction allows pillow block bearings to operate at higher speeds, but with lower load capacities than roller bearings. Bearing housings are available in a variety of configurations and are mounted on a surface parallel to the shaft to which the bearing is mounted. The bolt holes are usually slotted to allow for adjustment during installation. Pillow block bearing allows the shaft to rotate smoothly while the base supports the load. If you buy Pillow block bearings, you most likely already have some information about them. For those who are not familiar with pillow block bearing, we will use this article to introduce the basics of pillow block bearing.

7. After heat treatment, the ferrules must be sent to the material metallographic testing laboratory for strict metallographic and hardness testing;

11. The finished bearings are strictly tested for three items: rotation accuracy, bearing radial clearance, and bearing vibration and noise level. The vibration and noise level of the bearing has stably reached the V2 level requirements.

Steering Wheel Vibration: Another one of the most common symptoms of bearing wear could be a vibration coming from your steering wheel. This is because there will be a lack of control/stability and this symptom usually shows up when the vehicle is driving at slow speeds and will get worse as the vehicle accelerates.

The outer spherical bearing UCT with slider seat is a bearing assembly composed of a bearing and a bearing seat with guide grooves. Bearing seat T can be assembled with UK, UEL and other components. There are two chutes on the upper and lower sides of the bearing seat, which can move back and forth on the frame. Therefore, it is most suitable for occasions where the distance between shafts needs to be adjusted. The shafts can also move while the machine is running. The UCT300 series bears a greater load than the UCT200 series. This type of seated spherical ball bearings are mostly used on drive shafts such as belts and chains.

Excessive Play In The Wheels: Generally, you would have to take your car to a mechanic to detect this symptom. If you can jack your car up or it is on a hydraulic lift, you can try to move the wheel from one side, and if it wobbles or moves from side to side, then this could be a sign of a bad wheel bearing. If the wheel bearings are adequate, it will not wobble.

For the 3D drawing, we prefer to STEP, IGS or X_T format. The maximum supported file size is 10MB, For larger or multiple files please place into one folder and compress into a ZIP or RAR file and sent to info@aubearing.com

Aubearing has passed ISO9001 and 16949 quality certification systems. In 2022, Aubearing has customers in 30+ countries and regions around the world, achieving a revenue of US$30 million.

The UCPH series is a combination of PH bearing housing and Pillow Block Bearing. UCPH bearing seats are much taller than other types of bearing seats and are mainly used in special installation environments. The bearing seat is mainly made of cast iron, and stainless steel and plastic materials are used less than cast iron.

The UCFL series 2-bolt flange bearing unit is a design of a housed ball bearing unit, which consists of a UCFL housing and UC, NA, UE, UK, SB type Pillow Block Bearing, set screws and eccentric locking devices. FL bearing housing materials are available in cast iron, cast steel, plastic and stainless steel designs, and each housing and spherical bearing are interchangeable. UCFL standard type, widened inner ring bearing, set screw locking, cast gray iron bearing seat.

The design of the UCPA series pillow block bearing also has a certain degree of alignment, is easy to install, and has a dual-structure sealing device that can work in harsh environments. UCPA bearing seats are generally cast. Other common pillow block bearing types include UCP, UCF, UCFS, UCFC, UCFL, UCT, etc.

Wheel bearings are designed to last a very long time and they are made out of high-quality hardened steel. However, they are still susceptible to wear and tear, losing lubricity and they may become loose due to wear inside the hub assembly. If your wheel bearings break, your tyres and wheels could separate from your vehicle, which would lead to a very dangerous situation.

8613869596835

8613869596835